top of page

Rock Breaker Technology

Designed for surface and underground mining, as well as aggregate, construction, and demolition applications, we design and manufacture industry-leading rock crushing equipment driven by innovation.

With expert specialization in rock-breaking attachments, mobile equipment, and rock-breaking systems, our heavy-duty equipment delivers reliable and durable performance for increased profitability for modern jobs, no matter the size

NTE SERIES Rock Breaker System

MBS SERIES Rock Breaker System

MRH SERIES Rock Breaker System

applications

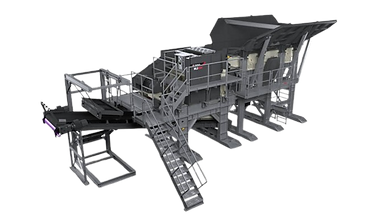

Mobile

Mobile crushers are, as the name implies, designed to be moved from site to site. An appropriate sized breaker system will mount on the crusher securely so the crusher can be moved without first dismantling the breaker assembly yet be large enough to handle the raking and breaking.

Grizzly

Grizzly applications are extremely harsh by nature. The boom is subject to high degrees of in-line and side raking, combined with various sizes and amounts of oversize. Grizzly booms are designed with wide boom cross sections, extra large pins and reinforced high tensile steel plates. All designed to handle complex loading to the boom.

Stationary

Jaw crushers and impact crushers are most often fed from a rock box using a vibratory feeder. A rock breaker should be positioned to assist with raking rocks into the crusher, reduce oversize, and to be able to reach into the crusher to assist with processing and clearing jams.

Gyratory

Big jobs need big booms and breakers. Wide range of gyratory booms allow full breaker coverage within the rock box and mouth of the crusher. Our complete line of large hammers are designed specifically for gyratories to quickly eliminate any bridging or clogging, restoring consistent material flow to the crusher.

bottom of page